Automated Inspection Solutions for Coins and Blanks

Why use automated inspection?

Protect your customers from quality issues

Increase your production rate with optimal efficiency.

Guarantee full compliance with regulatory requirements.

Reduce rework costs and meet delivery deadlines

Why work with us?

Unmatched performance in high-speed inspection for small and complex parts

Benefit from the latest innovations

- Rely on our 37 years of manufacturing expertise

Maximize your investment with long-term support and upgrades

30+ years of experience in minting industry

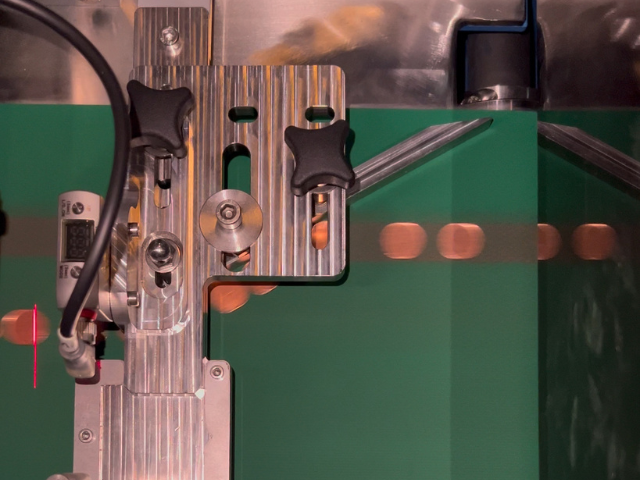

VISIA – Coin & Blank Inspection

- Throughput : Up to 200,000 coins or blanks per hour

- Inspection System : advanced 4-color matrix cameras and LED lighting for precise defect detection

- Inspection Scope : 100% surface inspection for coins and blanks across all shapes and materials, including scalloped, bi-metallic, and ringed designs

VISILAB – Precision Measurement and Analysis for Coins and Blanks

- Efficiency : Processes a 250-piece sample in just 30 minutes, saving time and resources.

- Precision : High-accuracy measurements with a repeatability of ±0.01 mm for diameter, ovality, rim height, and flatness.

- Versatility : Handles all circulating coins and blanks without the need for prior settings.

- Ease of Use : Intuitive operation with a self-calibrating system and optional conductivity and plating thickness measurement capabilities.

Innovation at the heart of our strategy

At the core of our coin and blank inspection machines lies the cutting-edge integration of artificial intelligence and advanced metrology systems. This state-of-the-art approach ensures unparalleled precision, consistency, and reliability in inspecting and measuring coins and blanks, making it the backbone of our technology.

Our commitment to leveraging the latest advancements in machine vision, AI, and edge technologies pushes the boundaries of inspection accuracy and operational efficiency. These innovations ensure exceptional performance, even at the highest production speeds, while meeting the stringent requirements of the minting industry.

At Proditec, innovation goes beyond technology—it reflects our vision and dedication. Through advanced tools and a culture of continuous improvement, we empower our team to anticipate future challenges, adapt to evolving needs, and maintain our position as a trusted leader in minting solutions.