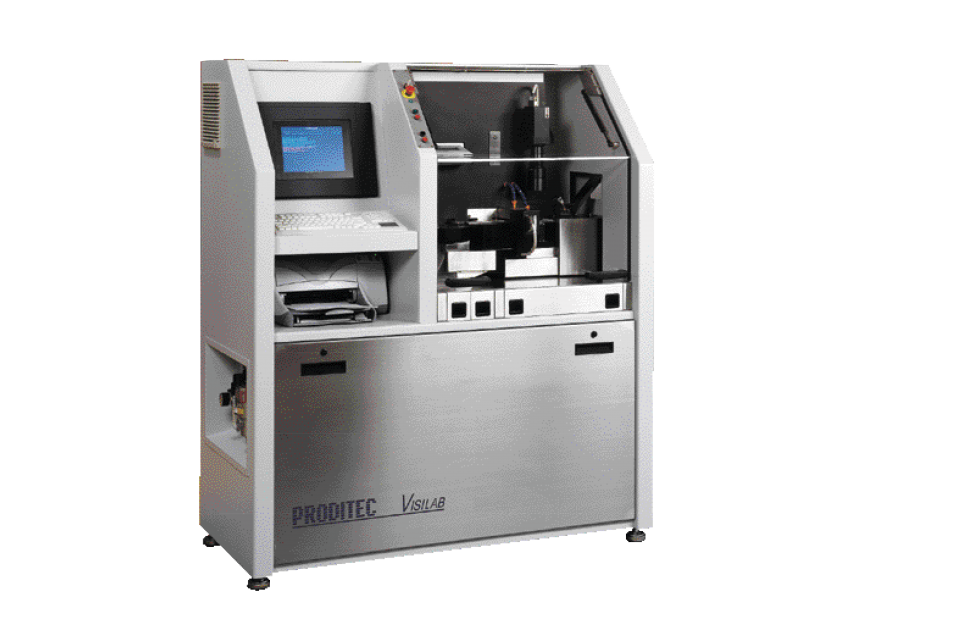

VISIA: High-Speed Inspection for Blanks & Coins

Common Features of the VISIA Machines

- High-Precision Inspection: Advanced vision systems ensure accurate detection of defects across all product types.

- High-Speed Operation: Capable of inspecting up to 200,000 coins or blanks per hour, supporting high-volume production needs.

- Material Compatibility: Supports a wide range of materials, including nickel, copper, aluminium, steel, and bi-metallic compositions.

- Shape Flexibility: Handles circular, scalloped, ringed, bi-metallic, and other complex shapes.

- Durable and Long-Lasting Design: Components designed for a minimum lifespan of 10 years.

- User-Friendly Interface: Touch-screen operation with intuitive menus for easy setup and operation.

- Advanced Software Integration: Includes real-time data monitoring, defect libraries, and smart settings for enhanced usability.

- Versatile Configurations: Customizable for blanks-only, coins-only, or combined blanks and coins inspection.

- Regulatory Compliance: Ensures high-quality standards for minting processes, reducing risks of defective production.

- Seamless Maintenance: Modular architecture and accessible design simplify repairs and upgrades.

VISIA Series – Inspection Solutions for Coins and Blanks

Tailored for your needs – VISIA machines seamlessly adapt to inspect coins, blanks, or both, ensuring precision and efficiency in every configuration.

| Features | Visia Only Coin | Visia Only Blank | Visia Coin & Blank | Visia Cash |

|---|---|---|---|---|

| Product Inspected | Coins | Blanks | Coins & Blanks | Coins |

| Maximum Throughput | 4,300 coins/min | 3,500 blanks/min | 3,500 blanks/min 4,300 coins/min |

4,300 coins/min |

| Dimensions | Ø 10–33 mm | Ø 10–30 mm | Ø 10–33 mm | Ø 10–33 mm |

| Specific Features | Removal of damaged and old coins High-speed sorting for circulating coins |

100% surface inspection for blanks | Dual-purpose inspection for coins and blanks | Detection of unfit and old coins Integration with real-time monitoring |